Strategy June 09, 2021

Behind Next Level's Eco Fabric: Recycled Poly (REPREVE®)

Just as Next Level Apparel is a driving force of the promo apparel space, so too is textile manufacturer Unifi in the realm of sustainability. As one of the largest producers of polyester fabrics and textiles around, Unifi recognizes that they have a responsibility to their customers – and to our planet – to do business in the most sustainable way possible. Their vision? “Make everyday life better by transforming the world’s products through sustainable innovation.”

It’s no wonder why Next Level was interested in partnering with this forward-thinking textile manufacturer, as the apparel supplier shares Unifi’s commitment to cutting-edge products and practices that transform the way we think of and use fabrics. Case in point: Unifi’s development of a sustainable performance fiber called REPREVE®, which Next Level is now proud to weave into their ECO product collection.

Next Level isn’t stopping there, though. To learn more about how Unifi develops their innovative fabrics and fibers, Carly Gerstman, Director of Corporate Social Responsibility, and Amanda Mitzman, Marketing Director, took a trip to Greensboro, North Carolina, to check out the Unifi headquarters for themselves. Not only were they hoping to better understand how REPREVE® fibers are made, they also had their eyes and ears open for new ways to collaborate together and further both companies’ sustainability goals.

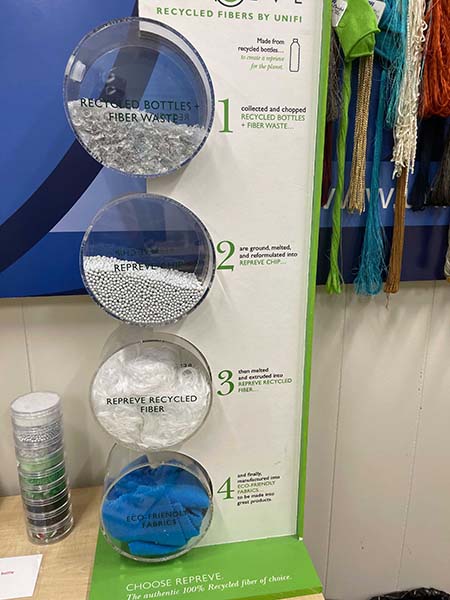

To kick off their two-day trip, Gerstman and Mitzman first set out to Unifi’s sorting facility, where the textile manufacturer receives tons of plastic bottles and containers each day, all ready to be recycled. Bottles are compressed into blocks, which are then run through a cleaning system before being sorted by color – blues and translucents in one category, greens and ambers in another. Labels are cleaned off by machines, and then bottles are melted down into slates before heading off to the next facility.

Gerstman noted how the streamlined machinery made short work of bottle preparation. In fact, Unifi relies predominantly on technology in their facilities to increase efficiency and reduce the chances of mistakes caused by human error.

Over at the next facility, slates are then cut into chips before being melted down again into pellets. Finally, those pellets are spun into thread before going to spinning mills to be turned into fabric – the end result Gerstman and Mitzman are more familiar with seeing on their side of the business. Both Next Level team members were impressed by the superb quality of the finished threads and fabrics, as well as the efficiency of Unifi’s facilities. After all, streamlined production upfront cuts down on waste, time and costs for everyone – even distributors and end-buyers who may not think as much about this stage of product development. You can truly see Unifi’s commitment to sustainability and innovation at every level – even literally, as their offices run completely on solar energy, via solar panels located on the roof.

Want to check out REPREVE® fabrics for yourself? Next Level’s ECO product collection is the perfect place to start. Using the very same REPREVE® fibers that Gertsman and Mitzman saw be created firsthand, these eco-friendly garments bring sustainability and style to the promo market like never before. Educate clients on all their earth-conscious benefits while you present the popular products below, each made with 40% recycled thread.

- Unisex ECO Performance Tee (4210)

- ECO Heavyweight Tee (4600)

- Women’s ECO Performance V (4240)

- Youth ECO Performance Crew (4212)

- CVC Recycled Adult Face Mask (M108)

- CVC Recycled Youth Face Mask (M109)

If there’s one thing we know for sure, it’s that this isn’t the end of Next Level's or Unifi’s sustainability journey. The only question is, what innovations will they bring to the promo industry next?