Strategy February 13, 2025

Decorating Roundup: Vantage Apparel Adds Chenille Patch Services

Also, Gildan offers DTG-friendly apparel innovation, and Vastex has released conveyor dryers specifically designed to cure DTF prints.

Key Takeaways

• Chenille Patches: Counselor Top 40 supplier Vantage Apparel (asi/93390) has introduced chenille patches to its decoration methods, offering a vintage aesthetic with vibrant colors, ideal for various garments.

• DTG-Friendly: Top 40 supplier Gildan (asi/56842) has launched Plasma Print technology to enhance direct-to-garment printing, reducing pre-treatment needs.

• High-Volume Spotlight: Stahls’ (asi/88984) highlighted US Colorworks, a large contract print shop processing up to 30,000 garments daily.

• DTF Dryers: Vastex introduced new conveyor dryers designed to protect operators from toxic ethylene glycol vapors emitted during the direct-to-film curing process.

Counselor Top 40 supplier Vantage Apparel (asi/93390) has added chenille patches to its lineup of decoration methods – combining vintage aesthetics with vibrant colors.

Vantage Apparel (asi/93390) now offers chenille patch decorations.

Chenille patches, crafted using a combination of felt and fluffy, tufted yarn, create a three-dimensional effect that’s soft to the touch but also visually striking. The technique is an ideal fit for varsity jackets, team apparel and fashion-forward garments.

“Whether celebrating achievements, promoting a brand or adding a retro flair, chenille patches provide a timeless and stylish solution for customization,” said Lauren Monnier, director of merchandising at Vantage.

Chenille patches have a low minimum order requirement of just 48 pieces, according to Vantage. Available in a wide range of colors and three sizes, the patches feature two layers of felt for added durability and are securely sewn down to garment to ensure a premium look and long-lasting wear, Monnier added.

Gildan Adds DTG-Friendly Style

Counselor Top 40 supplier Gildan (asi/56842) is showing off an array of new products and styles this year.

Among the innovations is its Plasma Print technology, which Gildan said is meant to enhance the direct-to-garment (DTG) printing process by reducing the need for pre-treatment on shirts. Plasma Print is designed to offer softer fabrics, brighter colors, improved ink coverage and enhanced print consistency, according to the supplier.

The supplier also noted that its Soft Cotton technology is being incorporated into its Light Cotton collection, offering customers a softer touch and improved printability qualities.

“The innovations and styles we’re introducing across our brands underline and strengthen our position as the industry’s preferred choice for decorators,” said Emma Budzisz, vice president of marketing at Gildan Activewear.

Stahls’ Highlights High-Volume Contract Print Shop

US Colorworks in Charlotte, NC, processes up to 30,000 garments a day.

In the latest episode of Stahls’ (asi/88984) Heat Press Transformation series, the St. Clair Shores, MI-based supplier spotlights US Colorworks, a large contract print shop just outside of Charlotte, NC.

Led by Dave Conner from Stahls’ Transfer Express (asi/91804) and industry expert Marshall Atkinson, the episode provides an in-depth look at how US Colorworks processes 25,000 to 30,000 garments daily – including 3,000 on-demand pieces – using a streamlined and highly automated workflow through Stahls’ Fulfill Engine. US Colorworks has 160 employees and integrates a diverse range of decoration methods, including screen printing, embroidery, DTG and direct-to-film (DTF) printing.

Stahls’ also announced that, for a limited time, it has reduced minimum order quantities for the high-end dimensional emblem and patch product category, allowing more decorators to expand their offering with a variety of valuable, retail-quality finishes. The company is offering customers the ability to order 12 patches for the same price per piece as 25 patches.

Vastex Conveyor Dryers Remove Glycol Vapor From DTF Curing Process

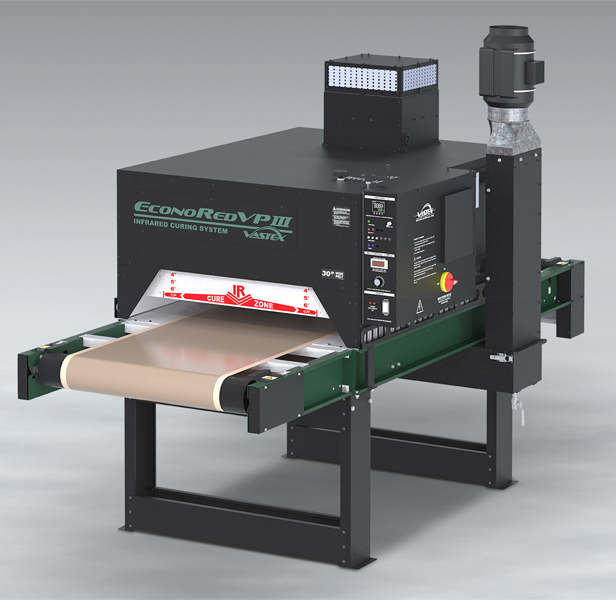

The ERVP-III-24 DTF-capable conveyor dryer protects shops from exposure to ethylene glycol vapor.

Two new DTF capable conveyor dryers from Vastex – the ERVP-III-24 and the ERVP-VI-24 – protect shop personnel from ethylene glycol, a toxic synthetic fluid emitted by DTF adhesives as a vapor during the curing process, according to Mark Vasilantone, president.

Engineered specifically for DTF curing, in which adhesives off-gas large volumes of glycol, the new dryers draw filtered makeup air through the top-center of the heating chamber, and through its double-wall top and sides, serving to cool the outer skin and chamber edges for operator safety.

“DTF printers must take caution that curing adhesive powders releases toxic vapors,” he said. “These Vastex DTF-specific dryers employ advanced air mapping to reduce exposure to these fumes and collect glycol condensate, protecting the operating staff as well as the dryer’s heating elements.”