Strategy March 10, 2025

Growth Opportunity: How To Capitalize on Printed Packaging

Understanding how to branch into custom paperboard packaging could enhance promotional products company’s services.

Key Takeaways

• Stability & Growth: Unlike other printing segments threatened by digitalization, packaging remains stable and offers significant growth opportunities. Promotional product suppliers can naturally extend their offerings to include packaging, as physical containers are essential for product distribution.

• Understanding Packaging Types & Processes: It’s important to understand various packaging types, such as folding cartons and corrugated packaging, and the associated printing and finishing processes. Entry-level producers can start with paperboard packaging, leveraging existing sheetfed digital production printers.

• Personalization & Durability: Personalization is a growing trend in packaging, especially for promotional products. Durable packaging is also crucial to protect products during delivery.

• Finishing & Embellishment: Packaging requires additional finishing processes like die cutting, folding and gluing. Embellishments such as embossing, debossing and foiling are important for making the package attractive.

Of all the segments of the printing industry, custom packaging arguably offers the most stability and opportunity for growth.

Unlike other areas of print that have shrunk or are threatened by digitalization, packaging isn’t impacted in the same way, as a physical container for a product can’t be digitized the way a bank statement can, for example. For promotional product suppliers, packaging could be a natural extension of their product offerings, given the likelihood that the products being distributed will be packaged in some way.

Cory Francer is an analyst at NAPCO Research, part of the PRINTING United Alliance – ASI’s strategic partner.

However, there are important elements for promo to consider before making the leap into packaging. Instilling a level of knowledge on the various packaging types, printing and finishing processes, and top-of-mind packaging trends are all key components of making a successful endeavor into the packaging industry.

Understanding Packaging Basics

While there are numerous types of printed packaging, the segment is often viewed through the lens of four primary subsegments: labels, folding cartons, flexible packaging and corrugated packaging. Let’s focus on paperboard packaging – folding cartons and corrugated – as flexible packaging provides a level of complexity not well suited for entry-level producers, and labels will be addressed in a subsequent article.

For folding cartons and lightweight corrugated boxes, the good news is that the production process for short runs will likely be familiar to those with existing printing capabilities. These products are typically produced on sheetfed devices, and with the proliferation of sheetfed digital production printers, the barriers to entry into paperboard packaging have been reduced.

On the folding carton side, these boxes are typically produced with a single-layer paperboard material, which can vary in weight and thickness. Because many existing sheetfed digital presses can handle lightweight paperboard, folding cartons can often be a logical starting point for those just getting into the segment. It’s important, though, to confirm with the equipment manufacturer that a digital press can handle the desired paper weight and thickness.

With corrugated packaging, it’s important to understand the differences between corrugated packaging for promotional products versus other high-volume uses. In the packaging industry, corrugated packaging is often conventionally printed in long runs, either direct printed with one or two colors, or with a separate printed layer that’s adhered to the corrugated material.

For promo companies just getting started in packaging, it’s best to consider corrugated packaging production in low volumes and small format sizes, perhaps for an event giveaway or a specific promotion that will be delivered to a select number of recipients. Because of the thickness of corrugated board, specialty printing equipment is likely to be required. Entry-level digital solutions have been released, however, and those with existing flatbed wide-format equipment may find it’s suitable to print on corrugated board, negating the need for new equipment.

Packaging’s Distinct Role in Promo

While traditional package printers often think about packaging through the lens of a brand owner and consumer, promotional products companies should approach packaging based on the needs of their specific industry. For example, rather than a consumer selecting a packaged product off a shelf, promotional products tend to be giveaways that serve to elevate and market a brand. One way of approaching promo product packaging is with kitting campaigns that extend custom branding from the promotional product through the package.

For example, in NAPCO Research’s Report Diversification Opportunities: Promotional Products and Apparel, Russ Truluck, CEO of Arden, NC-based Inform Systems Data Documents, shares his company’s success in creating a branded kit for the University of South Carolina’s medical school, consisting of a three-piece wine set that it could gift to alumni and donors.

“We worked with Bookwear in Minnesota to come up with a simple but outstanding packaging design in a cover and interior letter that allowed the gifts to be mailed or sent by UPS or FedEx,” Truluck said in the report.

Key Packaging Considerations for Success

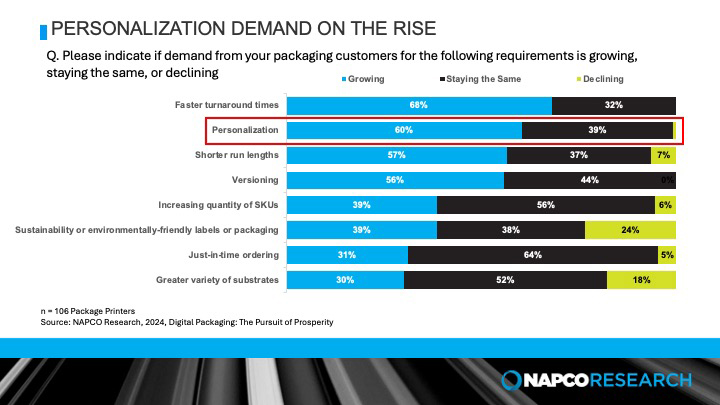

Once a printer has established that their customers need packaging, it’s important to recognize key success factors. For example, personalization is a growing opportunity in the packaging segment, and the promo space offers more opportunity for one-to-one personalization than traditional consumer packaging. Specifically, for an event giveaway, since the roster of attendees is likely already established prior to the event, a package could be personalized and handed to the attendee at check-in. Promo products distributors are likely to see demand for personalized packaging, as, according to NAPCO Research’s 2024 report Digital Packaging: The Pursuit of Prosperity, package printers are seeing increased personalization demand from their customers.

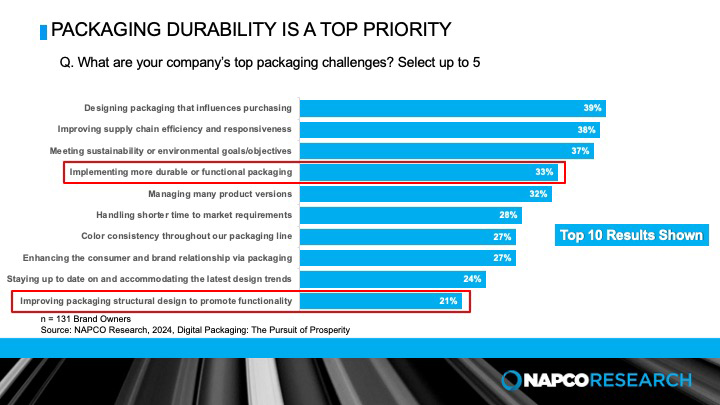

Beyond the printed components of the package, it’s also imperative that packaging producers provide solutions that will keep their customers’ products protected. While much of this article has focused on lightweight paperboard packaging, there may be instances in which a more robust package is required, and it’s often up to the printer to determine the best substrate for the job and ensure it can run on their equipment. For example, a promotional product such as branded golf balls can safely be packaged in a thin paperboard carton. However, a heavier product like a ceramic coffee mug will likely require a more durable container.

Durability in packaging is becoming increasingly important among brand owners. With the potential for damage throughout a product’s journey, whether it’s to a retailer or direct to consumer via e-commerce, ensuring the product stays protected is paramount. In the promotional product space, a product may be sent directly to a recipient, in which case it requires protection on that journey, or brought home by the recipients themselves, which can introduce any number of variables that could lead to product damage.

Understanding Finishing & Embellishment

Another way packaging, and paperboard cartons in particular, stands out from other printed products, is that after the printing process is completed, a series of finishing processes must occur for it to reach its final form. Specifically, folding cartons must be cut out of the printed sheet and folded and glued into shape. Additionally, packaging embellishments, such as embossing, debossing, foiling and specialty coatings are often added to make the package more attractive to its final recipient.

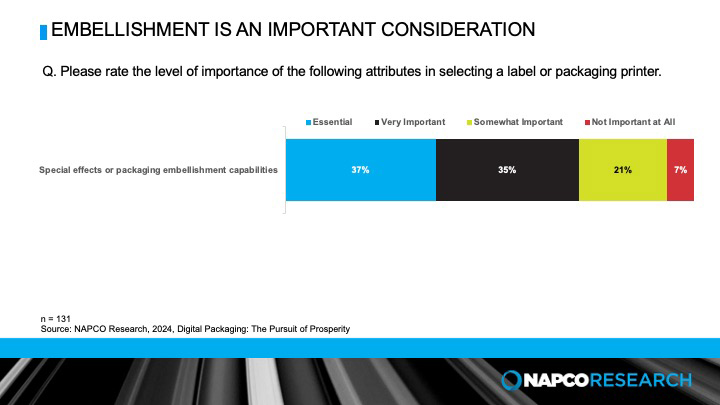

For promotional products providers, extensive finishing solutions are typically not necessary to handle the very short runs that likely will be required, as much of this work can be done by hand. However, when growing into more production-length packaging runs, investing in finishing equipment such as die cutters, folder/gluers and embellishment equipment could be necessary. In fact, according to brand owners surveyed by NAPCO Research, embellishment capabilities are a key component in their package printer selection process, as 72% of respondents report embellishment is either essential or very important in their selection process.

Conclusions & Recommendations

For promotional products companies seeking a stable and opportunity-laden expansion target, packaging is a logical choice. Promotional products necessitate packaging, and distributors that can source packaging from their suppliers will likely be appreciative of the opportunity to consolidate vendors. And with the advent and proliferation of digital printing platforms, the barriers to entry into the packaging segment have never been lower.

Despite the opportunity, however, there are key considerations before taking the leap into packaging. In addition to ensuring printing equipment can handle the packaging they aim to produce, promotional products companies should familiarize themselves with trends like personalization and increased packaging durability. Also factor in current design trends and the importance of sustainability in packaging.

Lastly, those getting into packaging should recognize there’s far more to creating a package than just printing. Die cutting, folding, gluing and many other finishing processes are key to creating a successful package. Embellishment is also top of mind for packaging customers, so learning how to enhance a product’s décor beyond print is key to standing out from the competition.

With the right education and equipment, however, packaging can prove to be a lucrative growth area for promotional products companies.

Cory Francer is an analyst at NAPCO Research, part of PRINTING United Alliance, ASI’s strategic media partner. In addition to content sharing, other initiatives launched as part of the partnership include a dual membership program and the ASI Show Pavilion – a “show-within-a-show” concept that will debut at the 2026 PRINTING United Expo in Las Vegas.