Product Hub October 23, 2025

PRINTING United Expo 2025: Make a Statement With Special-Effect Screen Printing

Decorating industry veteran Charlie Taublieb shared his expertise on how to up the perceived value of a garment with specialized printing techniques.

Key Takeaways

• At PRINTING United Expo in Orlando, veteran screen-printing consultant Charlie Taublieb defended traditional screen printing’s creative potential, saying he wanted to demonstrate “all the things DTF can’t do.”

• Taublieb showcased specialty techniques like high-density ink and discharge printing, which help to distinguish screen printing from digital transfers.

• He also highlighted foil printing as a way to achieve unique effects, encouraging decorators to combine multiple methods for eye-catching, premium apparel designs.

Over the last few years, it’s been nearly impossible to attend a print or promo trade show without being inundated with direct-to-film (DTF) printing. “Everyone is talking about how DTF is supposed to take over screen printing,” said Charlie Taublieb, a technical screen-printing consultant with half a century in the industry.

During a session on screen-printing special effects at PRINTING United Expo in Orlando on Oct. 22, Taublieb said he wanted to show off “all the things that DTF can’t do.”

To put it bluntly, the decorating veteran said, “This is my opportunity to tell DTF to stuff it.”

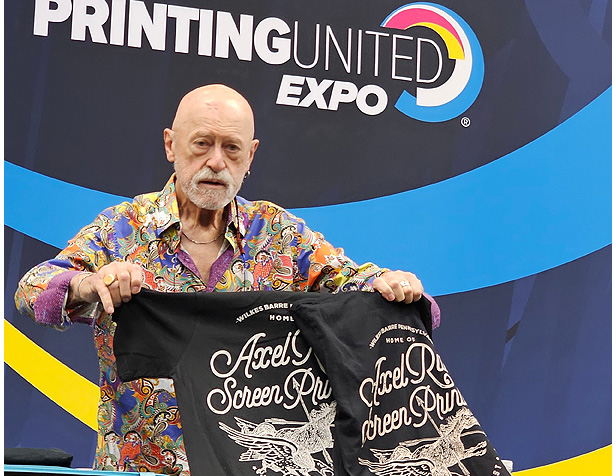

Veteran screen printer Charlie Taublieb shows off prints made using discharge inks during a session at PRINTING United Expo.

Though DTF printing handles small runs and detailed, full-color graphics well, Taublieb said it doesn’t open the same creative doors that traditional screen printing allows for. “What can you do that’s going to blow somebody away?” he asked.

Taublieb shared several screen-printing techniques – along with technical tips – to help apparel decorators take their designs to the next level and separate themselves from competitors.

High-density ink: High-density ink, Taublieb said, was really popular about a decade ago, before being overshadowed by puff inks. Both techniques result in a three-dimensional, textural print, though high-density ink builds a raised, crisp and often glossy look, whereas puff has more of a soft, sponge-like feel.

“You can do some really cool stuff with high density,” Taublieb said.

Playing with high-density ink allows printers to create layers, striations, ridges and other textures with their prints. But it also requires technical know-how.

Taublieb noted that it’s important to choose the proper mesh counts for screens and use a soft squeegee to ensure that you’re laying ink on top of the garment, rather than pushing into the fabric. “Print with too much pressure and you’ll crush it,” he said, adding that then, “It’s a dead shirt.”

Discharge ink: Another technique Taublieb touched on is discharge printing, where apparel decorators remove the dye from a fabric’s fibers, leaving either the garment’s natural color or replacing it with a different pigment. It’s a technique that’s been around for well over a century and is periodically “rediscovered” and iterated upon, he added. “We were doing discharge in the ’70s,” Taublieb said.

Discharge prints work best with 100% cotton garments finished with reactive dyes. It’s imperative to test before doing a discharge print, since not every color will discharge from a garment.

Another caveat? Color-matching designs on multiple garments can be a challenge unless the decorator takes meticulous notes, Taublieb said.

But discharge, especially when combined with other printing techniques, can result in eye-popping designs that command a premium price tag.

Foils: Foil printing involves printing a layer of adhesive to a garment, applying a thin metallic foil sheet, then using a heat press to make sure it stays. Pairing discharge printing with foils can lead to stunning specialty designs, Taublieb said.

He advised decorators to crumple up foil sheets before applying them. Not only does it create a unique distressed look, it sidesteps the hassle of trying to meticulously ensure the foil has no wrinkles, creases or other imperfections during application.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.